-

Band Sealing Machines (9)

-

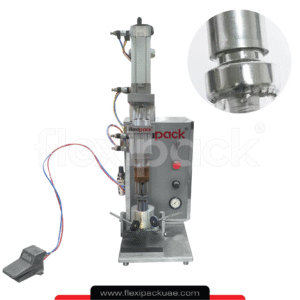

Capping / Closing Machines (26)

-

Carton Sealers & Strapping Machines (14)

-

Coffee Processing Machines (3)

-

Conveyors (15)

-

Date Coder / Printer (8)

-

Filling Machines (79)

-

Horizontal Flow Wrap Packing Machine (8)

-

Induction Cap Sealers (4)

-

Labeling Machines (16)

-

Overwrapping Machines (10)

-

Shrink Packaging Machines (22)

-

Spare Parts & Accessories (3)

-

Storage / Mixing Tanks (11)

-

Tube Sealing Machines (7)

-

Uncategorized (18)

-

Vacuum Packaging Machines (8)